Precision Machining & Assembly

ISO-9001-2015/AS9100D Certified

ITAR/DDTC Registered

- Mon - SAT: 7.00 am - 05.00 pm

- SUN: CLOSED

Precision Machining & Assembly

ISO-9001-2015/AS9100D Certified

ITAR/DDTC Registered

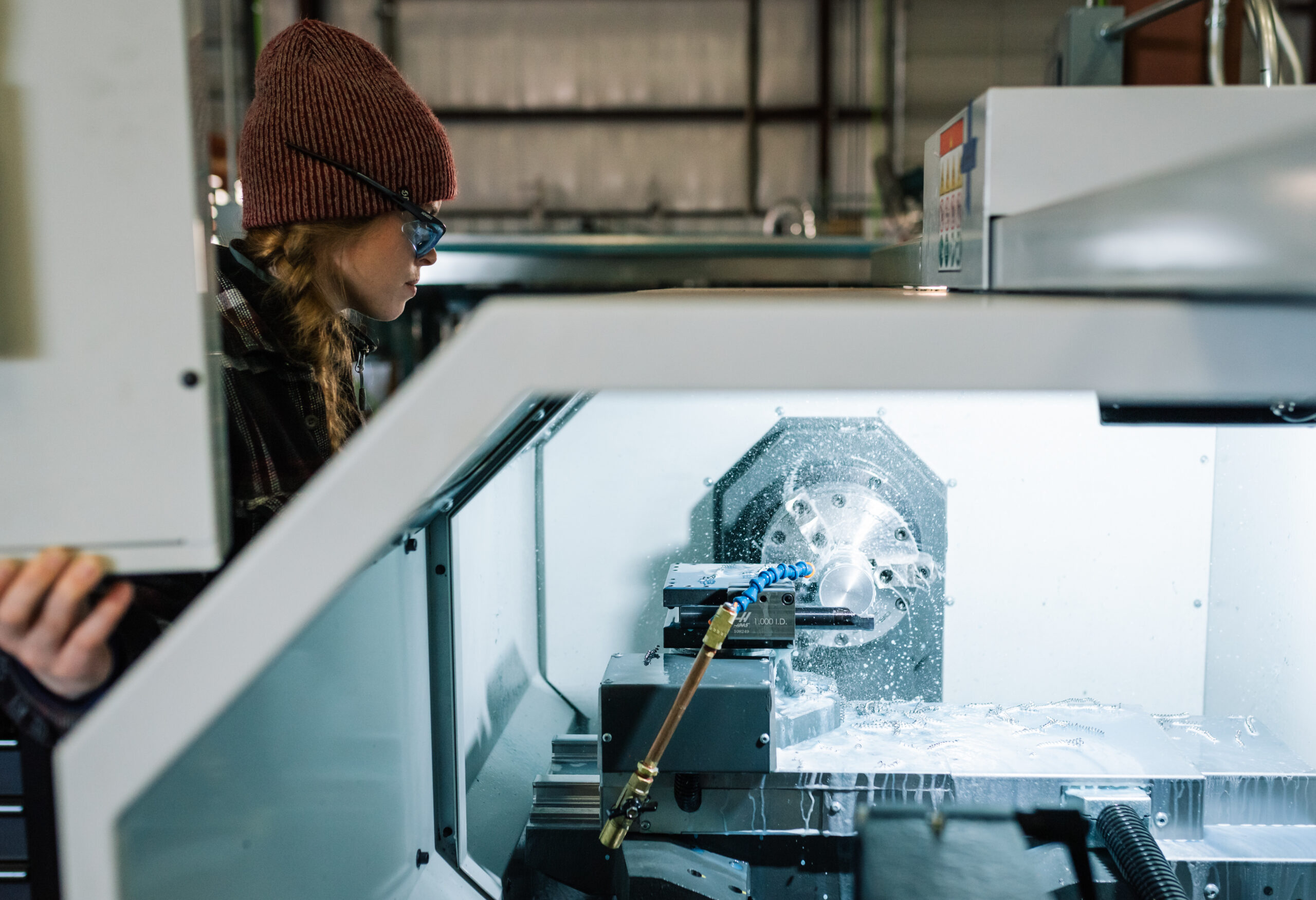

Our 35,000 square foot manufacturing facility can handle jobs big and small from milling to EDM to turning. Our capabilities include handling materials such as titanium, aluminum, stainless steel, teflon and more.

Facilities List

Electric discharge machining (EDM), sometimes colloquially also referred to as spark machining, spark eroding, burning, die sinking or wire erosion, is a manufacturing process whereby a desired shape is obtained using electrical discharges (sparks).

MKS manufacturers parts from a variety of materials– from aluminum to stainless steels and other exotic materials including plastics. The list includes: Aluminum 5052-H32, 2017,

Screw machines, being the class of automatic lathes for small- to medium-sized parts, are used in the high-volume manufacture of a vast variety of turned components.